RAW MATERIALS AND PRODUCTS

Flameless gasification of municipal waste opens up wide opportunities for production

According to the proposed technology, a wide range of municipal waste can be processed at the flameless gasification complex.

The main product of the process of processing the generated municipal waste at the flameless gasification complex will be synthesis gas, which, in turn, will become a raw material for the production of highly demanded commercial products (some of the lower ones are presented in the list below).

The coke obtained in the gasification process is sent to its own production needs.

In addition to energy resources, on gas piston or turbine plants - optional equipment of the world's largest companies, at the request of the customer, it is possible to produce a number of valuable export-oriented products.

In order to utilize excess heat and electric energy received at the complex, conceptually, our company offers to optionally introduce either a freezer or a greenhouse

TYPES OF MUNICIPAL WASTE FORMED TO BE PROCESSED AT THE FLAMELESS GASIFICATION COMPLEX

- PET bottles for water, drinks, vegetable oil and fats of various colors

- Tetrapac

- Household plastic (the entire list of household electrical appliances and devices, including their individual parts, toys and other household products

- Technical plastic for household needs

- Polyethylene and plastic film (including plastic bags and containers from it

- Textiles and articles thereof (including clothing, rags and fabrics of any origin)

- Hygiene products (pads, diapers, napkins, waddings)

- Waste paper in the form of paper and cardboard (containers and packaging, books, newspapers, wrapping paper, napkins, paper towels, writing paper)

- Rubber and household products made from it (including parts of household appliances and household appliances, shoes)

- Car tires, wheels of motorcycles, mopeds, mokiks and bicycles, baby carriages

- Shoes made of leather and leather substitutes for various purposes

- Other articles of leather and leather substitutes (bags, belts, belts, clothing, etc. and parts thereof)

- Wood and wood products (including foliage, grass, wood chips, sawdust, parts of trees and wood products)

- All types of food waste and biomass

- Glass of various colors and household use

- Black and non-ferrous metal

- Household construction waste

- Estimates, stones, ceramics, earthenware and sand

- Sewage sludge

MAIN STAGES OF THE PRODUCTION PROCESS:

WASTE

Generated municipal waste - raw material for production

Delivery of raw materials to the warehouse for subsequent submission for sorting

SORTING

Conveyor feed of raw materials for manual selection and sorting

Selection of secondary raw materials

THERMOLYSIS

Supply of sorted raw materials to the flameless gasification unit

Processing of prepared raw materials at the flameless gasification complex

SYNTHESIS-GAS

The use of synthesis gas for the production of commercial products

PRODUCTS OBTAINED FROM FLAMELESS GASIFICATION OF WASTE

- Methanol

- Formaldehyde

- Methylamines, dimethylamines

- Dimethyl sulfate, methyl methacrylate, dimethyl terephthalate

- Methyl halides

- Methyl tert-butyl ether (high-octane gasoline additive)

- Lower olefins

- High octane gasoline

- Fuel + DME

- Solvent

- Alcohols

- Acetic acid

- Proteins (microbiological synthesis)

- Nitrogen fertilizers (ammonia, urea)

- Others

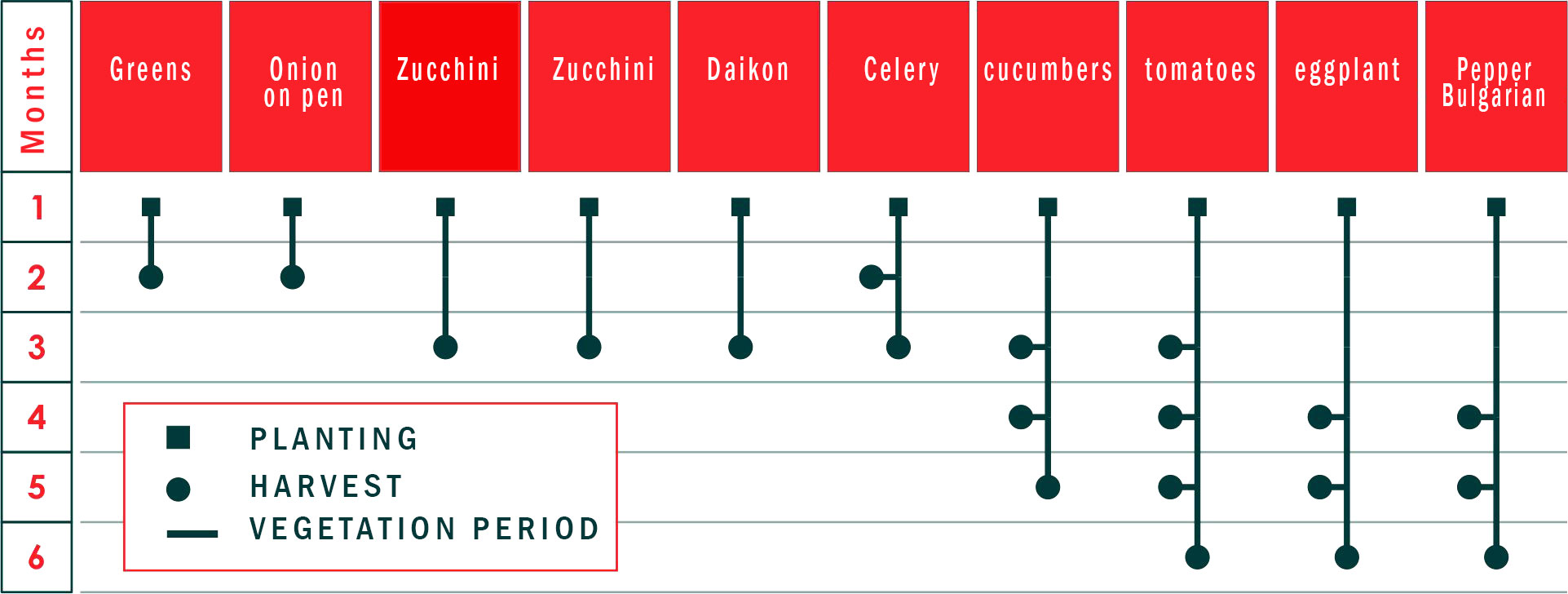

ORGANIZATION AT THE COMPLEX OF GREENHOUSE FACILITIES

The greenhouse facility offered as an option for construction is designed to use an efficient technology for growing a wide range of products - any kind of berries, vegetables and green crops. All types of plants can be grown in a 2-5 times shortened vegetative-technological cycle. The production and technological support of greenhouses allows for a year-round production cycle.

Growing in a greenhouse is as automated as possible. The level of temperature and humidity of soil and air, the intensity of air exchange, the amount of light, the supply of nutrients - all this is controlled by the executive and control equipment. All agrotechnical parameters of the greenhouse industry comply with international standards (CE, ISO).

High agrotechnical characteristics of greenhouses and automatic control of the cultivation process make it possible to obtain record yields. The installed greenhouse complex will achieve the following indicators (per 1 hectare, per year):- ordinary or cluster tomatoes - up to 700 tons;

- sherry tomatoes - up to 450 tons;

- sweet peppers (usually large, blunt-pointed, multi-colored) - up to 450 tons;

- cucumbers of different varieties - up to 700 tons;

- lettuce - up to 600 tons;

- garden strawberries or strawberries - up to 180 tons.

The moderate cost of a polycarbonate greenhouse complex allows for high profitability of such a production. This modern material is durable (guaranteed for 10-20 years), 40% lighter than glass, and has a transmission capacity for the most useful part of the sunlight spectrum. The high level of automation makes it possible to manage the workforce of 5 people per 1 ha of production area.

The complex of the greenhouse being introduced allows you to grow several crops simultaneously in the same greenhouse. The greenhouse is divided into separate sections by transparent partitions, which create an individual microclimate necessary for a particular crop in each zone and prevent the migration of pests and infections. The most varied combinations of crops and the timing of their cultivation are possible. Harvesting one crop can be combined with planting another. A greenhouse economy based on this principle makes it possible to quickly change the composition of crops in a greenhouse, quickly responding to current market demands.