THERMOTEC POWER Flameless Gasification Technology

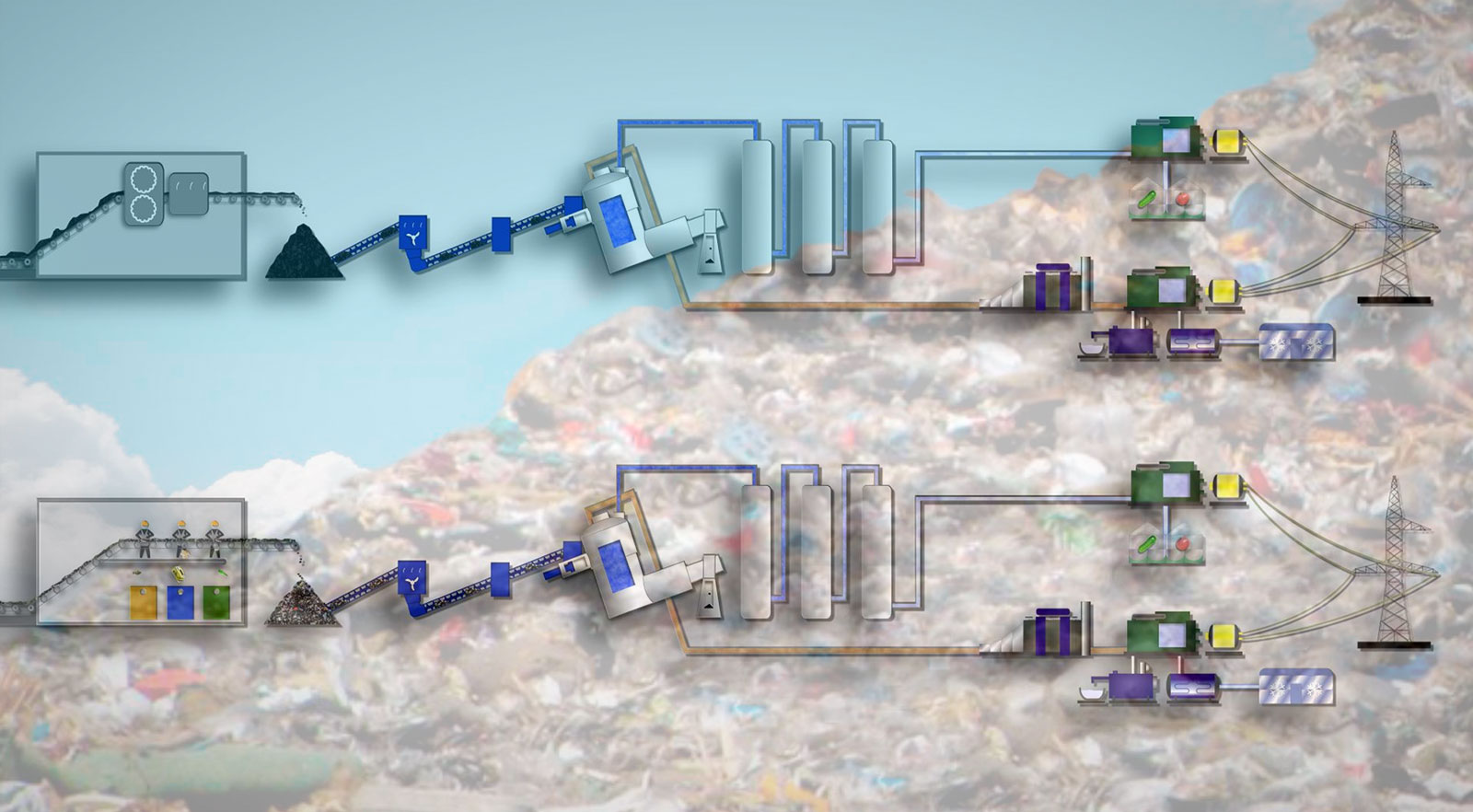

Advanced recycling process for waste, coal and other carbonaceous raw materials

We offer you to get acquainted with the Flameless gasification technology and briefly study the process underlying it, as well as evaluate only some of the technological, economic, environmental and other advantages of using the proposed equipment.

We will be glad to see you among our partners and clients!

Technology

Brief description of the process of processing raw materials using the equipment of the Flameless Gasification Complex

Raw materials, products

Flameless gasification of raw materials opens up opportunities for the production of a wide range of commercial products.

Аdvantage

The main advantages of Flameless Gasification technology: strengths and qualitative changes in its application.

Our offer

Our proposal for cooperation in the implementation of projects using our technology and equipment.

Main advantages of the application Flameless Gasification Technologies:

strengths and quality changes

Complex design modularity

Depending on the needs, Flameless gasification complexes of various sizes and capacities are possible.

Various raw materials supplied to gasification

Among the important innovations is the possibility of using raw materials of different origin and composition for gasification.

Achieving a uniform flow of the gasification reaction

Allows to transfer almost 100% of the organic part of the raw material into the gas phase

Flameless gasification in an oxygen-free environment

The gasification process is carried out without direct combustion and without the supply of air or oxygen.

Implementation of projects based on Flameless Gasification technology will allow:

- to raise the status of any region, city or settlement, making them advanced in the field of municipal waste management;

- to recycle or preserve and improve the majority of the existing and operated places of storage of municipal waste;

- reduce greenhouse gas emissions, contributing to compliance with the requirements of the 2015 Paris Agreement, and create conditions for improving the environmental safety of any region, city or settlement;

- create high sanitary and hygienic living conditions for the population;

At the same time, the implementation of projects based on Flameless Gasification will not require:

- allotment of land in regions, cities and towns for the organization of new landfills for the disposal of the resulting municipal waste;

- increasing tariffs for utilities for residents in regions, cities and towns for the disposal and deposition of generated communal waste;

- introduction and costly maintenance of separate collection of generated municipal waste in regions, cities and towns;

OBJECTS OF IMPLEMENTATION OF FLAMELESS GASIFICATION TECHNOLOGY

A plant in the city of Burgau (Germany) for the processing of 35,000 tons per year of municipal waste, where a flameless gasification reactor was used for the first time

A plant within the city of Leipzig (Germany) for the processing of 25,000 tons per year of organic raw materials. Completely built on a turnkey basis.